Extrusion helical gears

I recently just included Extrusion object into VRMath2 Editor and started to experiment its applications in creating 3D objects. It is quite easy to use Extrusion to create Spur Gears, but here I am showing how it can be used to created Helical Gears.

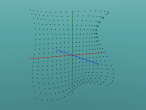

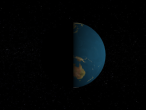

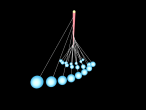

Extrusion starts with a crossSection, which is a 2D polygon shape on X-Z plane. It has a spine (usually along the Y axis direction) to define how many crossSections will be at certain 3D coordinates. Each spine coordinate has an associated scale (for resizing) and orirentation (for twisting) to create quite interesting extruded objects. The helical gear set below demonstrates the use of orientation to create the helical gears. Click on the big gear can toggle the animation.

Below are the Logo programs with some comments.

There are some strange behavious found when I use extrusion. For example, it is best to create extrusion at the coordinate 0,0,0. Or the orientation of extrusion will behave strangely.

I think extrusion can also be used to generate Bavel Gears and other types of gears. And I can create better tree trunk for my palm tree project.

Files: extrusion_helical_gears.x3d extrusion_helical_gear.logo

- Andy's blog

- Login or register to post comments

- 6720 reads

Comments

nice

Very nice, this is a great addition even if Extrusion in x3dom may not be 100% supported. Extrusion maps well to the egocentric turtle control and will make it much easier to create 3d, volumetric objects. It also leaves all the meshing to x3dom.

Why do you think you need an :angle of 22.5 for the large gear but 45 for the small gears ? I cannot figure out the reason.

Using Extrusion for the involute gears will make both the logo and the x3d much more compact.

angles

Using 45 degrees (for small gears) is a convinient guess for the 90 degree meshing gear. The angle 45 is then used as the total rotation (orientation) of the extrsution. The big gear has double number of teeth (so as the diameters, circumference) so its total rotation of extrusion is halved (inverse proportional, considering the gear ratio and rotation speed) in order to mesh. However, this only works for side by side helical gears. For the 90 degrees meshing, the inverse proportional relationship does not work, and I have not worked out their relationship. Any maths suggestions?

I have also tried using extrusion for bavel gear, but could not meshing them... Need to read more about gears.

depth

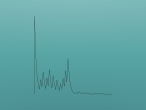

It turns out that the helical angle is not the angle by which the back face of the gear is rotated with respect to the front face. This total rotation angle in radians is tan(h) * depth / r where h is the helical angle, depth is the depth of the gear and r is the pitch radius. This can be derived by looking at the triangle which is formed the front, back and trace of a tooth.

I converted my involute gears to extrusions which speeds up the creation and rendering process a lot and made the code much more streamlined. It is now feasible to produce many nice gears in a single scene. However, begin and endcaps do not work in many but not all cases. So I will have to go back to manually adding in the back and front polygons, unfortunately. I will produce a new blog when this is ready.