Spur gears

Finally, not perfect at all but working gear set in 3D. Thanks to asplech's blog about involute gear and this Spur Gear document, I finally get to know better about these cogged wheels.

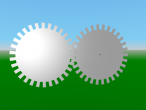

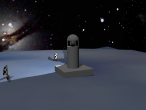

The 3D world below shows 4 gears meshing together. Because they have different number of teeth, they would have created some mechanical advantages/disadvantages in changing directions, speeds, and forces. Click on the cylinder can start or stop the animation. You can also navigate and zoom in to see the gears are actually meshing well.

The Logo program is commented below. I thought that I can make it short but still end up with almost 200 lines. The good thing is that you can change the pressure angle, diametral pitch, teeth number, and thickness. The gear generated should have same tooth length and as long as they have the same pressure angle and diametral pitch, they should mesh well. However, it will be a little bit tricky to spin at the right speed and direction, particularly when the number of teeth is an odd number.

The gear tooth is not as smooth as the involute gear. But it demonstrates a Logo way to collect circle coordinates and geometric shapes created later by connecting these coordinates. Same principle can be applied when I have implemented EXTRUSION, 2D coordinates can be collected as the cross section and be extruded. The rotation (SPIN) of the 11 teeth gear is a bit tricky. Line 175-176 collects the orientation and apply to the OrientationInterpolator's keyvalue in order to syn witht the gear ratio (applied to TIMESENSOR's cycleInterval).

Files: gear3d.x3d gear3d_proto1.logo

- Andy's blog

- Login or register to post comments

- 14240 reads

Comments

Mesh

The combined movement of the gears looks really good. Is it the example from the gear document for teaching ?

Good idea to customize the keyvalues. I ended up using two transforms.

Teaching gears

The gear document for teaching is a surprise I found online. It even maps to the English, Mathematics and Science and Technology standards for Year 9-12 in the US. One of my major goals of VRMath2 is to support the teaching and learning in STEM areas. That Spur Gear teaching document is a good example for this website.

I just noticed that it has many examples of meshing gears but I did not follow them when I did. I just want to try how to mesh gears with different numbers of teeth. A 3D world like that can teach/learn about gear ratio, rotation speeds and directions, which are topics in STEM. Of course, the best way of learning is for students to go though the construction as we did, not just see what we have created.

Yes, two transforms will work.. but I wonder why not one parent transform in my case... My gear coordinates are already rotated. This is something I need to look into...

You have spent much time on VRMath2 sites, which I really appreciate. I hope you found VRMath2 interesting and useful for some of your project.

Converted

I tried to import this gear3d.x3d into Blender and MeshLab and they both did, including the cylinder. This means that I can export as STL or PLY for 3D printing of gears.

This means that I can export as STL or PLY for 3D printing of gears.